The followings are usage examples of analytical measurements for powder characterization obtained by spray drying, spray cooling, and freeze granulation.

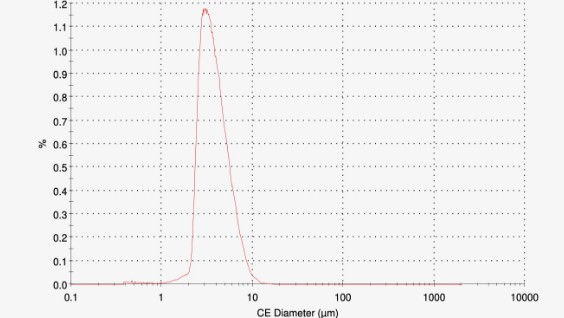

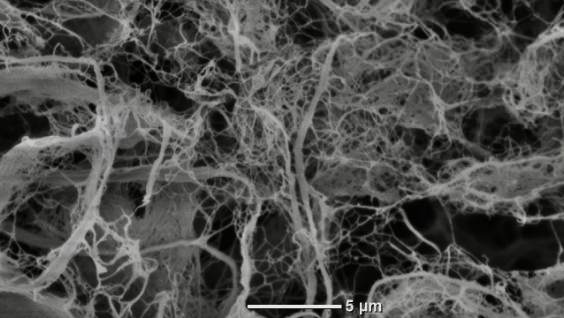

The particle size and shape of granules are analyzed using multiple image analyzers and a laser diffraction analyzer. The image analyzers can perform shape analysis such as particle size distribution and circularity, as well as brightness analysis of each individual particle. An online real-time laser diffraction PSD analyzer is also available to perform continuous particle size distribution analysis. SEM analysis is also conducted to observe the surface of particles.

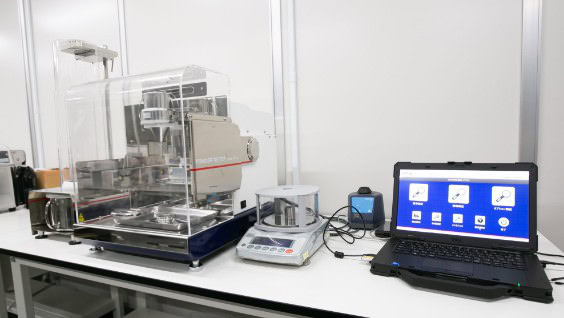

Powder characteristics analyzer and powder rheometer are used to analyze powder fluidity and flowability. In addition to the traditional methods of evaluating fluidity, such as angle of repose, bulk density and Carr’s fluidity index, dynamic analysis is also available to measure the actual behavior of powders in a dynamic environment. Dynamic rheometer can also analyze the disintegration properties due to frictions among flowing particles, making it possible to evaluate filling and handling properties of powders.

Analysis of specific surface area and density of particles is also important. We measure a specific surface area and pore distribution by constant volume method using gas adsorption. We also analyze true density and particle density by gas displacement method. Micro-particle crushing force measurement is also available to evaluate a particle strength by physically crushing a single particle.

The physical properties of a liquid material are also evaluated for parameters that affect the latter process: powder processing. In the case of slurries or suspensions, the particle size distribution is measured using laser diffraction analysis. By circulating a liquid material and continuously measuring the particle size distribution, it is also possible to evaluate changes in cohesion, disintegration and re-dispersibility. We also perform rheology analysis using a wet rheometer for dynamic flow behavior such as viscoelasticity, shear stress, cohesive/dispersion stability, thixotropy and dilatancy properties, and yield point.

Please contact us via the contact form or by phone.

We will discuss the outline of your plan by phone, email, face-to-face, online, etc. We will also provide information about our Powder Technical Center and inform you possible facilities to be selected and time slots available. Depending on the facility selected, reservations may be booked for several months, so we ask you to schedule your appointment early.

Please fill out and submit the Trial/Contract Processing/Analytical Measurement Confirmation Sheet. You can skip items that are unclear or non-disclosure information. *We ask for detailed disclosure regarding the safety and environmental information.

We will submit you a quotation based on the Trial/Contract Processing/Analytical Measurement Confirmation Sheet.

The trial date will be fixed after we receive your formal request.

Ship your material by the day before the trial date. If you visit our PTC and observe your trial on the day, you may bring your material with you.

If you observe your trial on the day, we will conduct the trial while discussing operating conditions with you. Even if you are not present, we can adjust the conditions while reporting the progress over the phone.

A report will be submitted within one week from the trial date.