We focus on particulate matter (PM) emission control (EC) in boilers, furnaces, and dryers.

We also work on enhancing powder recovery (PR) in pharmaceutical, food, and chemical processes.

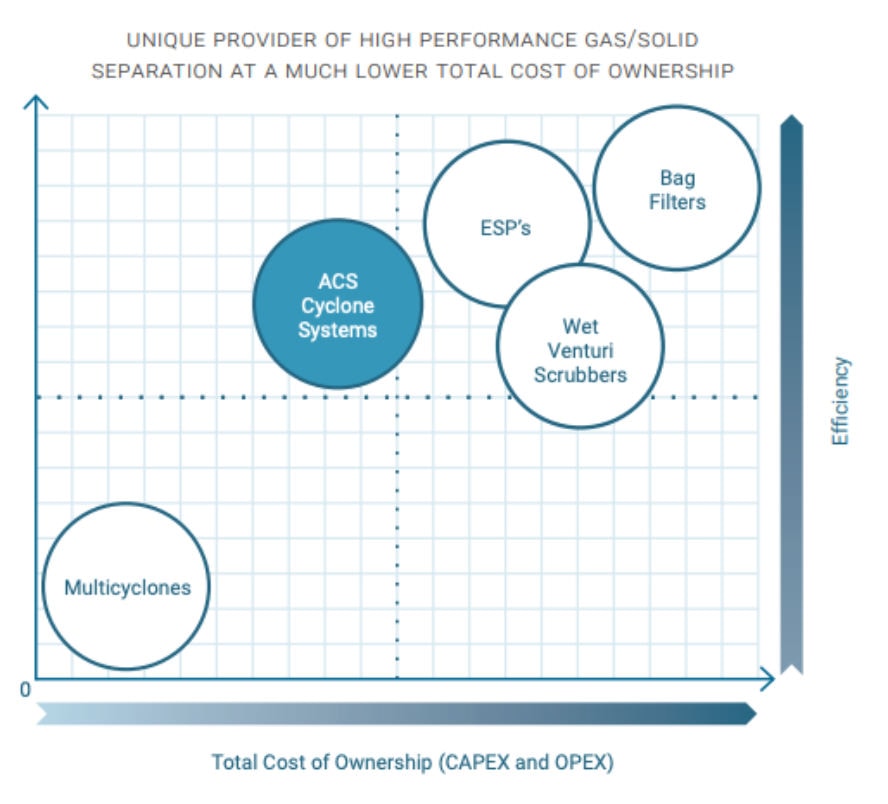

Achieving particle capture exclusively with cyclones by continuously researching and innovating, freeing the client from the costs and problems of Electrostatic Precipitators (ESPs) and Bag filters (BF).

We work in close cooperation with our clients, designing customized cyclones that solve their filtration problems. Unlike most cyclone providers, we give strict guarantees of emissions and efficiency.

ACS cyclone systems contradict the general thinking that cyclones are inefficient powder collectors.

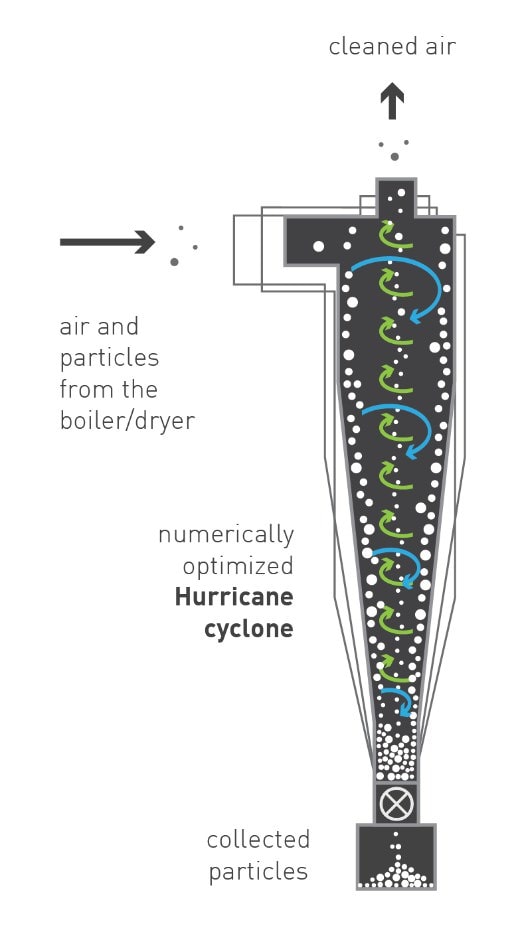

Hurricane cyclone geometries, with the possibility of recirculation (ReCyclone Systems), have proven to be an alternative to ESPs and BFs in numerous plants all over the world to comply with strict limits, reaching emissions as low as 30 mg/Nm³.

We have a specialized scientific knowledge in particle agglomeration modeling (PACyc) and numerical optimization in partnership with the Engineering Faculty of Porto (FEUP), where we run a pilot system for R&D.

The revolutionary concept of particle agglomeration is essential to explain how cyclones really work and, consequently, to optimize them. The outcome of our research is not a universal solution but a set of very different cyclone families and systems serving particular client needs and customizable for each given application.

Hurricane cyclone families respond to a particular need from the client and considering how inter-particle agglomeration/cluster- ing affects collection efficiency. From coarse particle pre-separation proportioned by compact and low pressure drop cyclones, such as the SD and DX, to fine particulate capture with high-end geometries such as the EX and MK, ACS provides solutions for a wide range of industrial cases, being able to reach emissions comparable to ESPs (down to less than 30mg/Nm3).

ACS holds accurate efficiency prediction models, capable of explain- ing why sub-micrometer particles are often captured with much higher efficiency than expected. Particles with bigger agglomerates (clusters) are easier to be collected than the original particles. Agglomeration increases in the presence of wide particle size distributions and it causes long residence times in the cyclone and high inlet particle concentrations. This mechanism are incorporated in ACS numerical simulation, combining a sophisticated stochastic algorithm with a classical numerical model to predict cyclone perfor- mance: the PACyc (Particle Agglomeration in Cyclones) mode

Together with economic and operation constraints such as size and pressure loss, PACyc Model allows to simulate millions of virtual prototypes with numerical optimization within an affordable period. The numerical optimization have resulted in several families of cyclones, some of those patented. The following cyclone families, always subject to further customization, are the result of very different client demands ACS has come across until now.

Depending on the requirements of the client, ACS designs solutions that go from compact pre-separators to a final stage dust collector. The more efficient the solution is, the larger the number of cyclones needed to increase residence time and promote particle agglomer- ation. ACS offers the most cost-efficient solutions by considering the impact of space and cost.

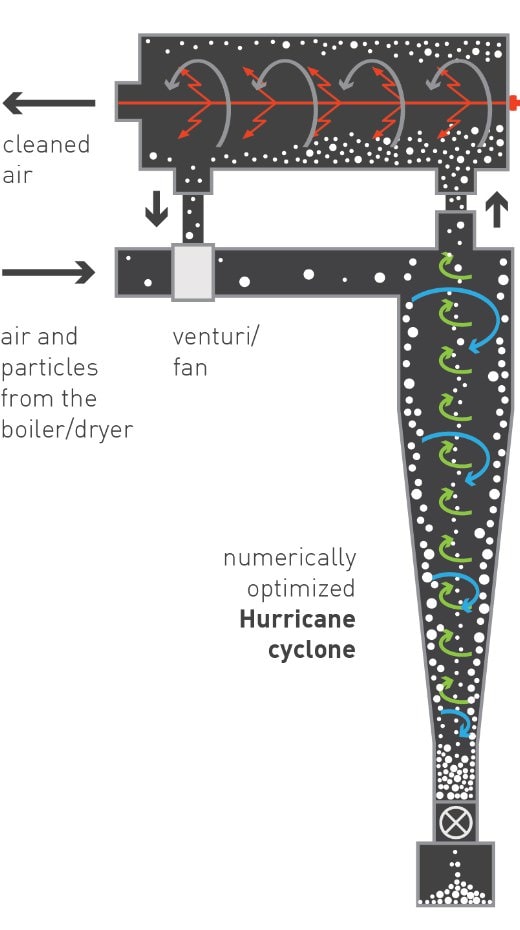

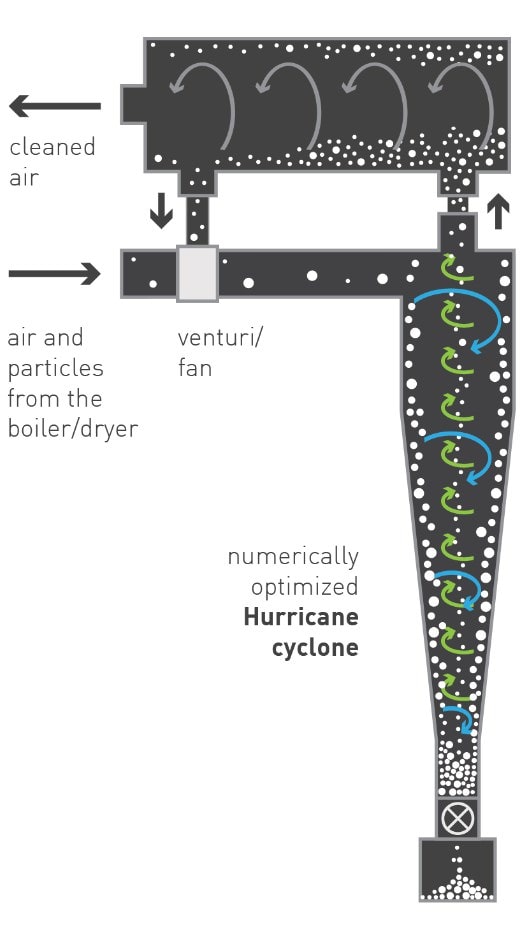

ACS holds a patent of a recirculation system to increase the efficiency of cyclones. ReCyclone is made up of a high efficiency Hurricane and a particle separator, placed downstream, called the “mechanical recirculator”. The main purpose of the recircula- tors is to reintroduce the uncaptured particles into the cyclones after those fine particles are driven to the outer walls of the recirculators by centrifugal force. While the process gas is enriched in particles, the axial exhaust gas stream is clean with less particles. Recirculation is achieved through an additional fan. Since the recirculation system only serves as dust separation (and not collection), the particles are exclusively collected in the cyclones. The system is a combination of a cyclone and a recirculator. Efficiency increases due to recirculation and agglomeration of fine particles with larger ones coming directly from the process. ReCyclone® MH decreases emissions of Hurricane cyclones by 30 to 60%. Recirculation control has the benefit of handling variable process gas flow rates.

An adoption of electrostatic recirculation in the cyclone system has successfully proven to further reduction of particle emissions, even in the 1-5μm particle size range, assuring future regulation compliance, particularly where legal limits are very strict. DC high voltage is applied to the recirculator, allowing the recirculation of very fine nanometric particles, more resistant to centrifugal forces, to the cyclones. After separation in the recirculator and concentration in the recirculation flow, electrically charged fine particles are attracted by the cyclone walls, while agglomerating with larger particles entering the system – both promoting their easier capture. Unlike ESPs, particles are not captured on the walls of the recirculator so that ReCyclone® systems can avoid dust accumulation and condensation. Additionally, ReCyclone® EH systems have low sensitivity to either low or high electrical resistivity while required power is only 10 to 15% of that used in ESPs.